SPECIALTY OPERATIONS

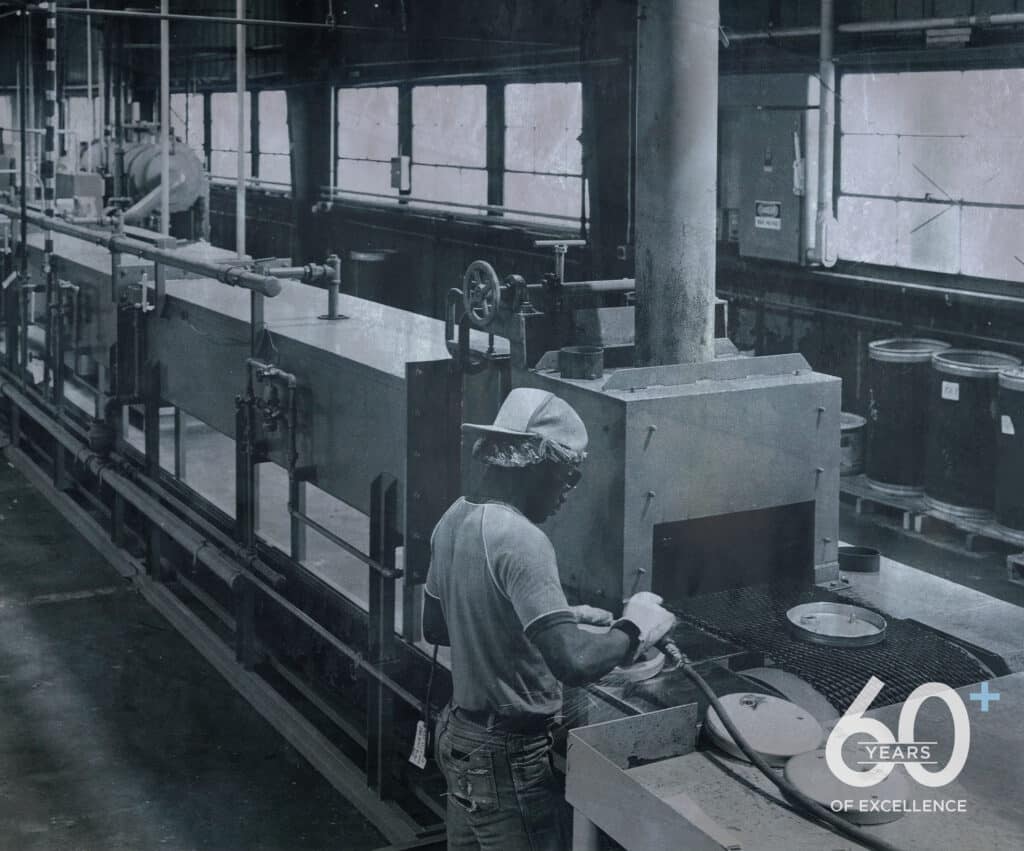

Built for High Volume. Backed by 60+ Years of Precision.

We specialize in high-precision machined parts. If you require quality, you have found the right source. Lewis Engineering is dedicated to providing a quality product at a competitive price. This dedication is visible in the CNC turning centers, CNC machining centers, and automatic screw machines available for your job. These machine tools are supported with centerless grinders, broaching machines, and milling machines for auxiliary operations. Our capabilities permit the completion of complex parts with the least number of setups and a minimum amount of time, thus reducing costs.

STAMPING

Need stamped parts at scale? For 60+ years, Lewis Engineering has been known for speed, consistency, and capability. Our stamping department is equipped with presses running from 22 to 300 tons, air-cushioned for compound die work and built for high-volume output. Just send us a drawing, and we’ll take care of the rest.

ASSEMBLY

When your machined part is just one piece of the puzzle, we’re ready to build the whole thing. Lewis Engineering has the tools and systems to handle high-volume assembly – custom drills, dedicated assembly lines, and automated glue applicators. We take care of it all, so your components are delivered complete and production-ready.

WELDING

Lewis Engineering provides both spot welding for high-volume assemblies and precision welding for joining complex parts. By keeping this capability in-house, we eliminate delays, reduce part movement, and ensure consistent weld quality from one unit to the next.

BROACHING

Broaching is a fast, cost-effective way to achieve precise shapes and internal features without tying up CNC machines. We use specialized broach tools to remove material quickly and cleanly, ideal for slots, keyways, and other consistent geometries. It’s a smart solution for customers looking to reduce machining time and simplify production.

LASER ETCHING

Lewis Engineering uses laser etching to permanently mark parts with lot numbers, part numbers, or other identifying information without slowing down your production. Our process delivers clean, legible results on every part, ensuring traceability and compliance with your documentation needs.